A Guide to PDCA and driving organizational change

Summary

In this guide, you will learn:

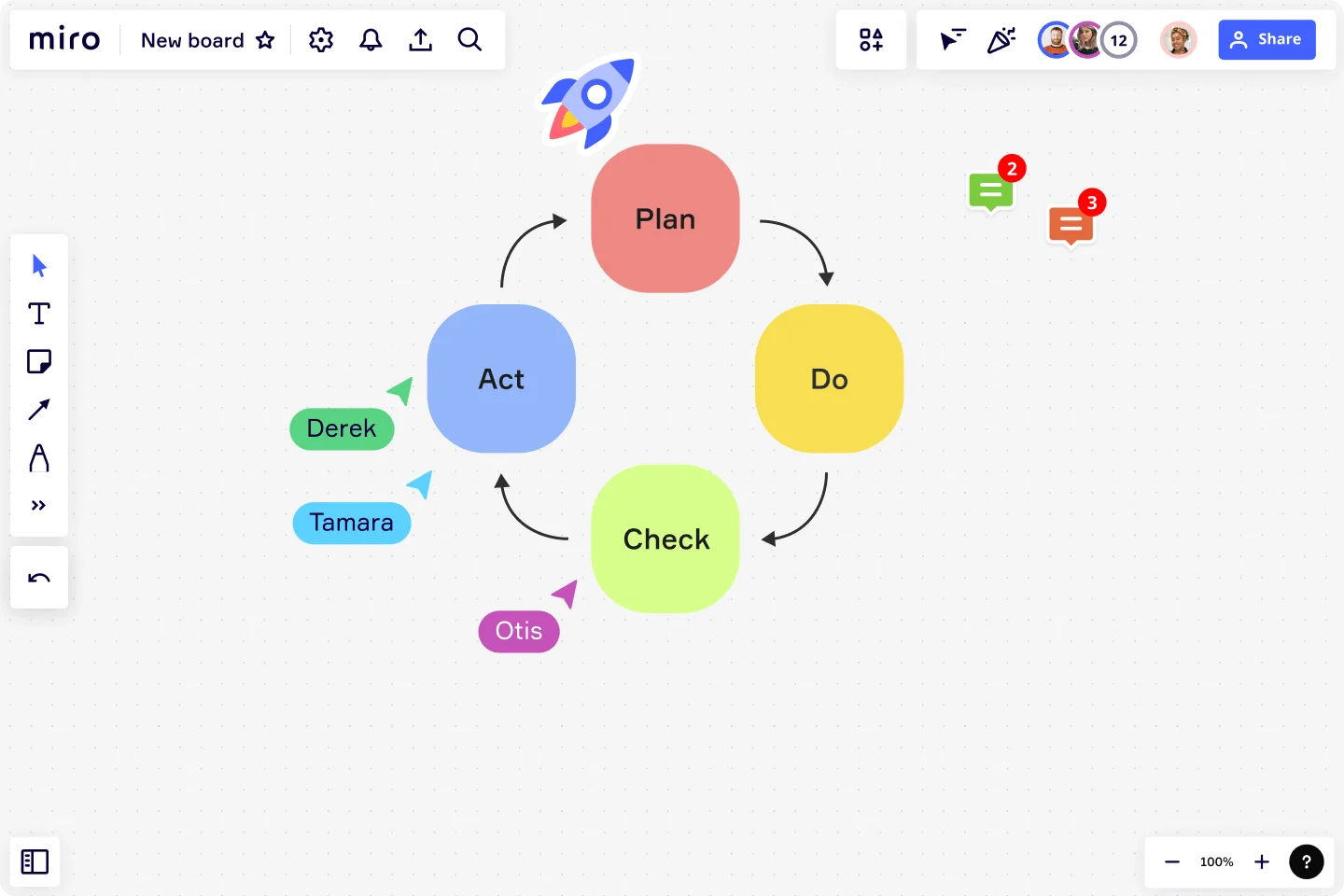

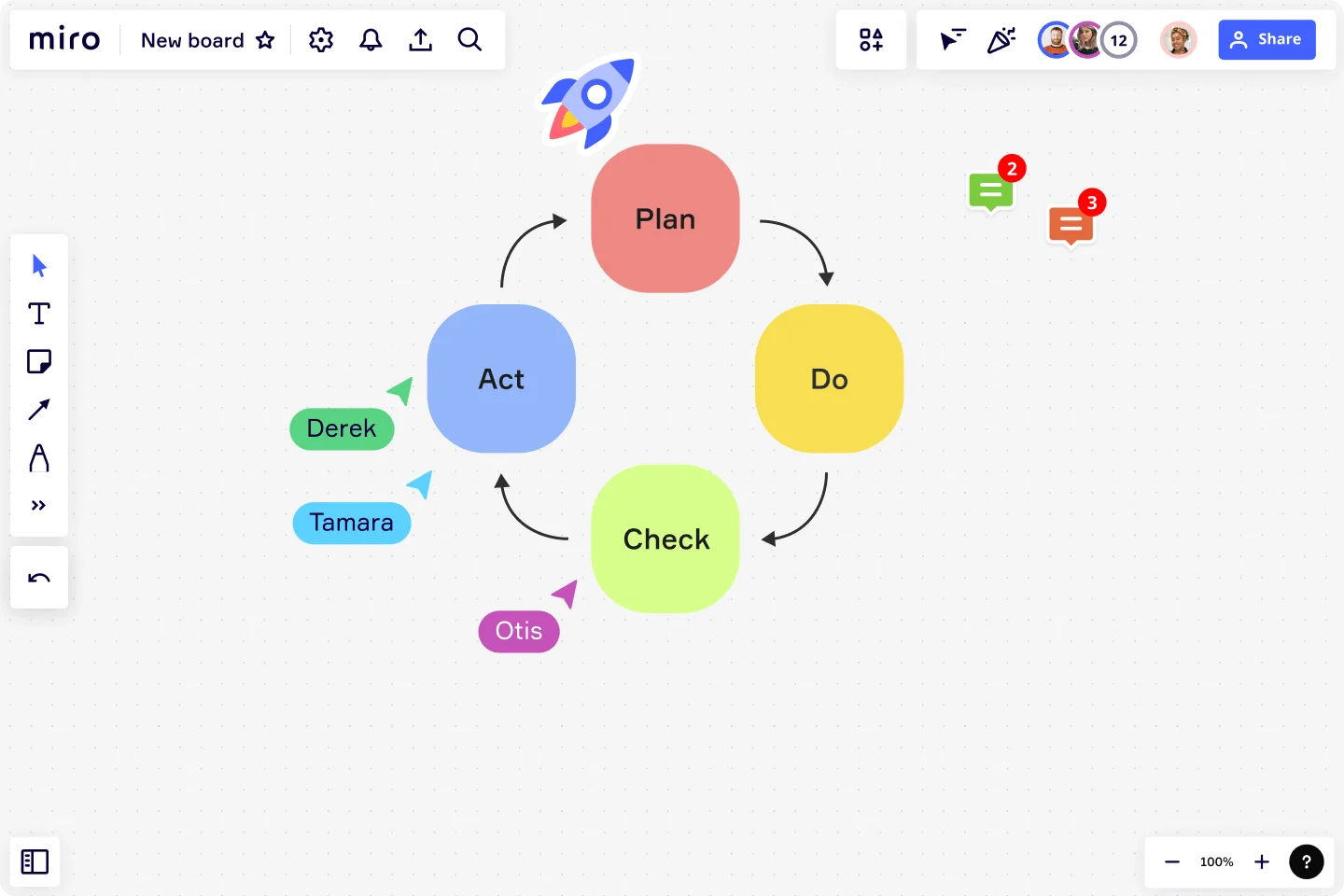

The **PDCA cycle** (Plan-Do-Check-Act) is a four-step iterative management method for continuous process and product improvement.

The cycle involves **planning** a change, **doing** a small-scale test, **checking** results against expected outcomes, and **acting** to implement improvements or adjustments.

PDCA is widely used for quality control, problem-solving, risk management, and implementing changes in various industries.

The method supports continuous improvement by repeating the cycle to refine processes and prevent recurrence of issues.

PDCA helps organizations develop compliant management systems and supports certification to standards like ISO.

It is effective for streamlining workflows, testing multiple solutions quickly, and minimizing errors while maximizing outcomes.

Guide to the PDCA cycle

Every organization needs continuous improvement.

It is challenging to work out what needs improving, but it’s also hard to work out how to improve these issues, so they have strong positive effects on your business.

PDCA, short for Plan, Do, Check, Act, is a popular problem-solving and continuous improvement methodology that’s been around for almost a century.

In this article, we’ll explain how PDCA works, why it’s an important tool for strategic planning, and how it’s being used in action.

What is PDCA?

PDCA (also known as PDCA Deming Cycle) is a cyclical continuous improvement methodology designed to help organizations understand their issues, improve their processes, and reach their goals.

Each of the four stages is as important as the next. The steps work in unison as a continuous cycle to drive improvements by constantly revisiting a process to identify its weak links as it evolves. This makes it easy for organizations to find opportunities to improve proactively.

What are the stages of PDCA?

PDCA is a method for continuous improvement. It has four stages that work as a cycle to drive progress over time.

The stages are:

Plan: Find the issue or opportunity, set goals, and plan how you will address the problem or grasp the opportunity.

Do: Put the plan into action and track how well it goes.

Check: Go through the data and determine what worked and what didn’t.

Act/Adjust: If your plan worked, standardize the results. If it didn’t, adjust and start again at the “Plan” stage.

But here’s the clincher. You have to keep returning to a process, even if it seems to be working.

You need to identify the new weak links that crop up as your process changes. That way, you can leverage those insights immediately to reach your goals faster instead of getting blindsided in fluctuating markets.

Why’s PDCA important?

PDCA isn’t a wand to wave away your problems. It’s an iterative process that guides you through continual improvement so you can reach your project goals more efficiently.

Here’s why it’s such an important tool for your organization:

Continuous improvement: By repeatedly running through the PDCA cycle, organizations can refine their processes. That way, they reach their goals faster and improve efficiency over time.

Cost savings: PDCA focuses on cutting down waste and reducing errors. This helps businesses drive down costs related to fixing errors and resource waste.

Standardization: PDCA can help you figure out what works so that you can standardize processes and procedures. Standardization enables you to train your teams so there are fewer errors and people are more effective.

Problem-solving: PDCA provides a structured approach to identifying opportunities and solving issues. This helps organizations make strategic decisions systematically.

Collaborative teamwork: By involving employees at all levels in the improvement process, you build a culture of continuous improvement. This creates a sense of ownership and accountability that drives people to want to innovate.

Customer satisfaction: You can use the PDCA methodology to improve customer success processes to increase customer satisfaction and loyalty.

Data-driven decisions: It’s no longer a guessing game. PDCA encourages you to collect data to make informed decisions rather than risk wasting time and money on something that doesn’t work.

Risk reduction: By considering potential problems before they occur, PDCA can help organizations plan around risky situations to help prevent costly mistakes.

Organizational learning: PDCA is grounded in learning and experimentation. Failures are opportunities to improve. Building a culture of feedback and innovation strengthens your team's agility.

Strategic alignment: It’s rare for organizations to reach their long-term company goals all in one go. It’s usually thanks to lots of little processes working together over time. PDCA helps you strategically align these processes bit by bit.

When to use PDCA?

While PDCA is a powerful tool, it can’t do everything. Here are the times it’s best to use it:

Strategic Planning: At the beginning of your journey, PDCA can help you define clear goals for your projects.

Process improvement: If you want to find out your weak spots and improve the flow of your operations, PDCA is ideal for improving process efficiency and effectiveness.

Quality control: If you’re getting poor results, PDCA can help you pinpoint the problems in the chain.

Problem-solving: If you need a concise methodology to solve a definitive problem, try PDCA.

Product Development: PDCA can help you test new ideas, refine specifications, and evolve products into new markets.

Examples of industries and fields that use PDCA:

PDCA is used across all industries to improve manufacturing, customer service, and efficiency. Here are some prime examples:

Manufacturing: PDCA is often used to improve production efficiency, reduce overheads, and increase high-quality output.

Healthcare: PDCA can improve patient experiences, rectify quality and safety issues, and reduce costs.

Education: PDCA can be used to enhance teaching practices and refine student learning outcomes.

Information technology: PDCA can streamline software development processes, weed out bugs, and drive innovation.

Service industries: PDCA is used across many service sectors, including banking, hospitality, and retail. It helps to improve customer experience and streamline operations.

Limitations of PDCA

While PDCA is excellent for driving continuous improvement, it has its limitations. Here are some scenarios where PDCA isn’t the best fit.

Incremental improvements: If you’re looking to make small changes to specific processes over time, PDCA isn’t the right tool. It’s better suited to addressing big-picture issues or strategic changes.

Divergent problem-solving: If you need out-of-the-box ideas, you may need a divergent approach. PDCA is quite a rigid methodology, which can be limiting in a project’s ideation and brainstorming stages.

Tight for time: PDCA takes strategic planning and requires a lot of thought from a whole team of people. This is time-consuming and resource-intensive. It’s not ideal for urgent solutions.

Limited data: PDCA encourages you to assess your data analytically. If you don’t have the time or resources to collect and organize this data, you’ll find it hard to implement the PDCA method.

Alternatives to PDCA

PDCA isn’t the only continuous process improvement methodology.

Here are some other well-known constant improvement theories to enhance quality management and identify opportunities for improvement in your business processes.

Six Sigma

Six Sigma is a data-driven methodology focused on making decisions through statistical analysis to reduce systematic defects and hone quality.

Like PDCA, it’s a cyclical process that involves measuring, analyzing, upgrading, and monitoring.

By using Six Sigma, organizations can pinpoint the root cause of problems and work on efficiency, productivity, and customer satisfaction.

Here are the steps:

Define: Define the issue or opportunity, set goals and objectives, and put the team together.

Measure: Define your key metrics and collect data on the issue.

Analyze: Analyze your data to understand the root cause of the problem.

Improve: Develop and test solutions.

Control: Create a plan to monitor and control your implemented solutions.

PROS:

It’s based on data-driven decision-making, using hard evidence to get answers.

There’s an emphasis on improving quality for better processes rather than just cheaper or quicker methods.

It’s a structured approach to problem-solving that’s easily repeatable.

CONS:

There’s a potential for over-reliance on statistical analysis, neglecting personal experience and expertise.

It’s quite a rigid approach that doesn’t allow for out-of-the-box thinking.

Theory of Constraints

The Theory of Constraints is a management methodology to identify and eradicate constraints that hinder an organization's capacity to achieve its targets.

Instead of focusing on individual components, this philosophy concentrates on optimizing the entire system. The goal is to pinpoint and solve constraints so they don’t have adverse knock-on effects elsewhere.

The idea is that a system is only as strong as its weakest link. By continuously going back to the whole process, you can identify new weak links as they crop up.

Here’s the process:

Identify the constraint: Work out the weakness that you think is limiting the system.

Exploit the constraint: Make sure the constraint functions to its full capacity and take corrective action to fix anything that’s not working right.

Subordinate everything else: Align all other tasks in the process to help support the weak link.

Elevate the constraint: Improve the constraint as best as possible by investing in new equipment, technology, or specialist staff,

Repeat the process: Keep running through the same process to identify the weak links as they occur.

PROS:

The focus is on removing constraints that limit the system so that the weak links get stronger.

It aims to fix the whole system, not just one component. This limits knock-on effects from changing one part of the process independently.

It encourages a systems thinking approach among teams that flows into other areas of their work.

CONS:

You must know the system very well to find constraints.

Sometimes you need a lot of investment to fix a constraint.

It can be time-consuming as a process, and teams may not have the capacity to run consistently as a continuous approach.

Examples of PDCA in action

The PDCA cycle has been widely adopted across all kinds of industries.

The two most famous examples are Toyota and NASA.

Toyota was one of the first large companies to employ the Japanese business philosophy. By using this approach, Toyota has been able to reorganize its manufacturing processes to cut out waste, streamline production, and improve quality.

Aerospace industry leader, NASA, used PDCA to improve the safety of its space shuttle program. By pinpointing areas that required higher safety measures, NASA wasn’t only able to eliminate some of the dangers but also improve the reliability of the program.

Visual tools to help with the PDCA process

Miro has a PDCA Template to help you with planning, ideation, and visualization — all fundamental components to effectively implementing the PDCA cycle in any organization.

Ideal for putting PDCA thoughts on ‘paper,’ Miro makes it easy for teams to collaborate on continuous improvement projects.

Here are some of the best templates to help your PDCA process.

Analyze the problem

Before you begin with PDCA, you need to identify the areas for improvement.

The SWOT Analysis Template is ideal for identifying the strengths, weaknesses, opportunities, and threats of your current process or previous iterations.

This model helps you to brainstorm the internal and external factors that affect your organization’s capacity to achieve its objectives. It also enables you to identify the key issues or main opportunities to work on. This makes it easier to prioritize improvements.

Most importantly, this template provides an easy-to-digest diagram to make your issues more visually accessible to your whole team.

Devise action steps

When planning the actions you need to take to improve your processes, it’s a good idea to create a roadmap.

Product Roadmap Templates helps you plot the steps your team needs to take and assign deadlines to those actions. This means that you have a clear plan to follow in the ‘do’ phase of the cycle, so everyone is accountable for their role.

The template is super easy to use, with the process or product on the left and the action steps over different phases on the right. Your team can tick off actions as they’re completed, so you can always see progress.

Review changes

While the Quick Retrospective Template is most often used for projects working within the Agile methodology, it can also be applied to teams using PDCA.

During the ‘check’ phase of the cycle, you can create an overview of what’s working, what’s not, what can be altered, and what to do next.

The template helps your teams break down the results of any actions taken in a clear visual way. That way, what needs to be changed and what can stay the same is evident.

Document the PDCA Cycle

The PDCA is an ongoing process. That means you’ll likely have lots of notes from different PDCA iterations. Rather than lose documentation or try to remember everything from scraps of paper, Miro’s handy PDCA Kaizen Cycle Template gives you a simple-to-read diagram to break down each step of the process.

By documenting all four steps, you have a record of what you’ve tried over time. That way, you won’t repeat strategies that failed in the past.

PDCA drives continuous improvement

The cyclical nature of the PDCA makes it a powerful tool for organizations to improve their processes and achieve their goals continuously.

By providing a structured approach to problem-solving, PDCA can help organizations identify problems and opportunities, improve quality, reduce overheads, and boost customer satisfaction.

If PDCA is the right methodology for your business goals, sign up to Miro to collaborate on the planning and review stages.

Author: Miro Team Last update: August 13, 2025